Product Brief Introduction

Product Brief Introduction

Environmentally friendly gasification continuous carbonization furnace is a carbon-containing material ( It is an ideal equipment for dry distillation, oxygen-free carbonization and high carbonization rate under high temperature conditions in the furnace. This machine reasonably adopts the advanced technology of recycling, purifying and cyclic combustion of combustible gases such as carbon monoxide, methane and oxygen produced in the carbonization process of materials. It not only solves the problem of environmental pollution caused by the thick smoke produced by ordinary carbonization furnaces in the carbonization project, but also solves the problem of thermal energy required by the equipment, fully achieves self-supply, improves the continuity and economy of the equipment, and makes full use of various The leftovers can turn waste into treasure, alleviate the contradiction between the supply and demand of forestry resources in my country, and make more contributions to the greening environment.

Product advantages

Product advantages

Product Parameter

Product Parameter

| Equipment model classification | THJ-Ⅰ | LXTHJ-Ⅱ | LXTHJ-Ⅲ |

| Pipe diameter (mm) | Ø800*1200 | Ø1000*1600 | Ø1200*2000 |

| Equipment output (kg/h) | 400-500 | 600-800 | 800-1000 |

| Fan power (kw) frequency conversion speed regulation | 7.5 | 11 | 15 |

| Continuous carbonization machine main engine power (kw) speed regulation | 4 | 5.5 | 7.5 |

| Cooling charcoal machine motor power (kw) | 3 | 3 | 3 |

| Screw feeder motor power (kw) | 3 | 3 | 3 |

| Burner(s) | 1 | 1 | 2 |

| Liquefied gas burner (pcs) | 8 | 8 | 8 |

| Auxiliary burner (pcs) | 1 | 1 | 1 |

| Working temperature of high temperature carbonization pipeline (℃) | 500-800 | 500-800 | 500-800 |

| Furnace temperature (℃) | 350-800 | 350-800 | 350-800 |

Charcoal is a macroporous high-carbon product obtained by sub-stoichiometric heating of wood beyond atmospheric ignition temperature. The structure and properties of charcoal are determined by the time/temperature regime of pyrolysis. Industrial charcoal is obtained at a final pyrolysis temperature of 450-550 °C. Pyrolysis of wood (dry distillation of wood) – decomposition of wood when heated without access to air with the formation of gaseous and liquid products and a solid residue – charcoal.

![]() Working principle and process

Working principle and process

Brief description of the production process

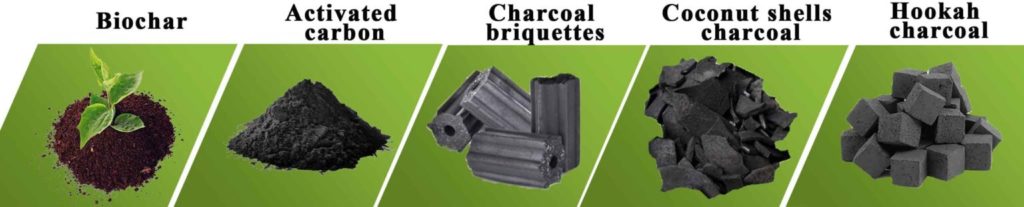

Product Application

Product Application

Raw materials